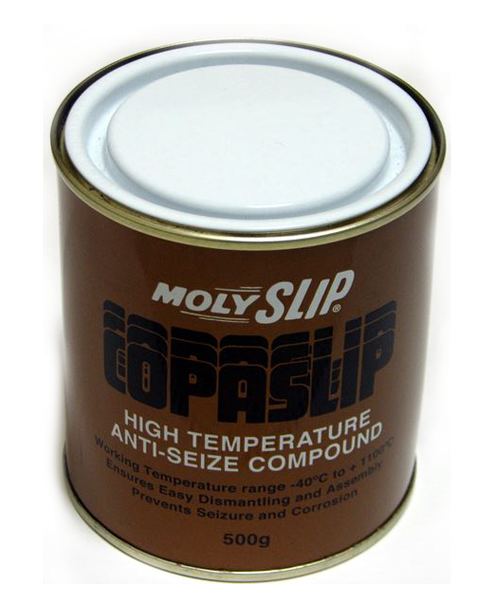

COPASLIP® is an anti-seize compound specially formulated to protect against seizure even in extreme conditions of temperature and pressure. It also protects against rust, oxidation and other corrosion. COPASLIP® consists of micro-sized particles of copper in a semi-synthetic base. To these basic anti-seize ingredients are added highly effective oxidation and corrosion inhibitors. The unique combination of properties in COPASLIP® ensures rapid and easy assembly of threaded parts. It allows correct torque to be applied by eliminating thread interference.COPASLIP® prevents seizing and galling and gives quick and easy breakout of threads, gaskets and packings even after long exposure to high temperature, corrosive conditions or extreme surface pressures. It also reduces wear in areas of high friction. By protecting against seizure, maintenance work requiring routine or infrequent assembly and dismantling is made much easier and less costly.

Molyslip Copaslip is an anti-seize pre-assembly compound for use in any temperature from sub-zero to 1100ºC (2000ºF). It has extremely high film strength and has been formulated and produced to provide:•Protection against seizure — even in extreme service conditions •Ease and economy of labour when assembling and dismantling equipment •Protection against rust, oxidation and other corrosion, especially with dissimilar metals

Pure metallic copper dispersion in a semi-synthetic base.Operating Temperature Range ............................................ - 40°C to +1100°C (-40ºF to 2000ºF)Solidifying Temperature ..................................................... - 18°C (0ºF)Unworked Penetration at 25°C (ASTM D217) .................... 310–340Contained fluid .................................................................... vaccum distilled mineral oilDrop Point ........................................................................... non-meltClosed cup flashpoint (ASTM D93) ....................................... 243ºC (470ºF)Neutralisation Value (ASTM D974) ..................................... Four-ball weld test (ASTM D2596) ...................................... passes at 400 kg (881 lbs)K factor ............................................................................... 0.16Solubility in water ............................................................... insoluableCovering Power .................................................................. ≈ 8m² per kgCorrosion Resistant ............................................................ complete in 10% hydrochloric acid andsaturated salt solutionsSpecific Gravity .................................................................. 1.13Shelf life .............................................................................. 24 months under original seal